1.Sturcture

The structure of the emergency sprinkler: the main structure includes control valve, spray head, valve drive device.

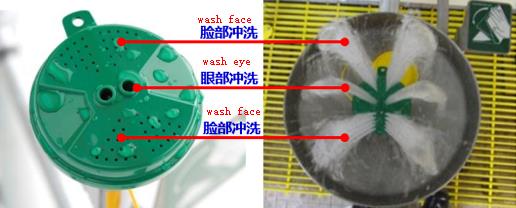

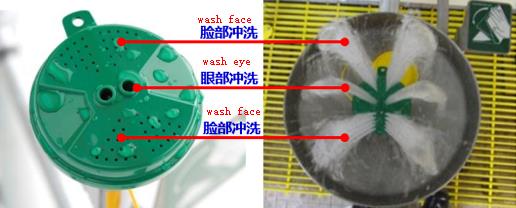

The structure of the eye washer: The main structure includes the flushing liquid conveying pipeline, nozzle, control valve and valve driving device.

2.Time

● When the installed eye washer only has the function of eye washing, the rinse solution should be automatically ejected within 1s or less after the eye washer is started. The duration of continuous use shall not be less than 15min, and the flow rate of the flushing fluid shall be at least 1.5L/min.

● When the eye washing nozzle is equipped with eye washing/face washing function, the flow rate of eye washing solution should be at least 11.4L/min, and the duration should be not less than 15 minutes.

● When the sprinkler is started, the rinse solution should be automatically ejected within 1s or less. The sprayer should provide rinse solution at a flow rate of at least 76L/min, maintaining continuous flushing for at least 15min.

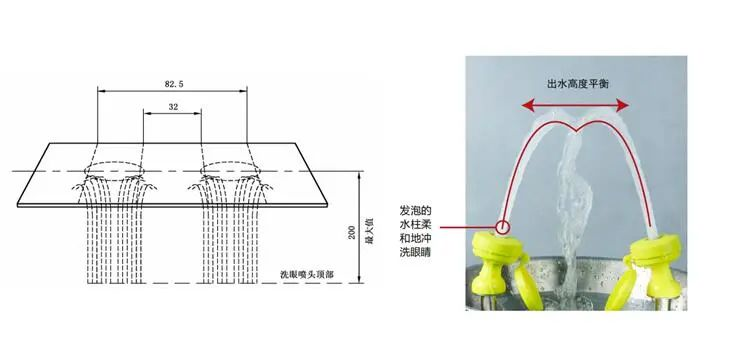

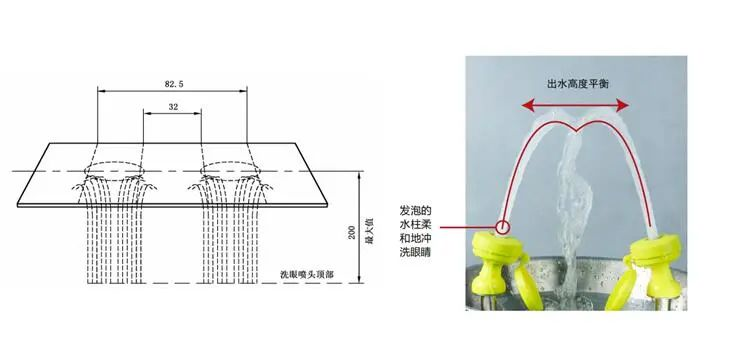

3.The water level

● The rinse solution shall be contained in the area line between the inside and outside of the standard ruler located less than 200mm above the eye wash nozzle.

4.Position arrangement

● The emergency spraying and eye washing equipment should be installed in the area within 10s within the reach of the operator (in general, when a person walks at a normal pace, the average distance can be 15m in 10s).

● The eye washer should be installed on the same plane as the area where the danger may occur. At the same time, the route to the equipment should be considered to avoid obstacles.

5.Temperature

● The appropriate temperature range of the flushing liquid at the inlet of emergency spraying and eye washing equipment is 16ºC to 38ºC. While rinses below 16ºC immediately slow down chemical reactions, prolonged exposure to cold fluids can affect the body's required body temperature and cause premature interruption of emergency care.

● If the ambient temperature is higher than 38℃, the equipment equipped with high temperature protection device is recommended, or the equipment should be properly cooled or insulated.

● If there is a possibility that the washing liquid may freeze, it is advisable to choose equipment with anti-freezing protection (self-empting, anti-freezing protection valve) and carry out thermal insulation treatment.

● If there is the possibility of long-term icing, it is advisable to choose equipment with anti-freezing protection (electric heat insulation), or appropriate heat insulation treatment.

6.Mantainment

● It is recommended to check, maintain and record the emergency spraying and eye washing equipment at least once a week.

● If any component is damaged during maintenance, replace it in time. If necessary, replace the damaged device.

● The most important thing for employees who may come into contact with hazardous materials is to ensure that they know the location and proper use of emergency spraying and eye washing equipment. First aid training is essential before the equipment is installed and put into use, and then every six months.